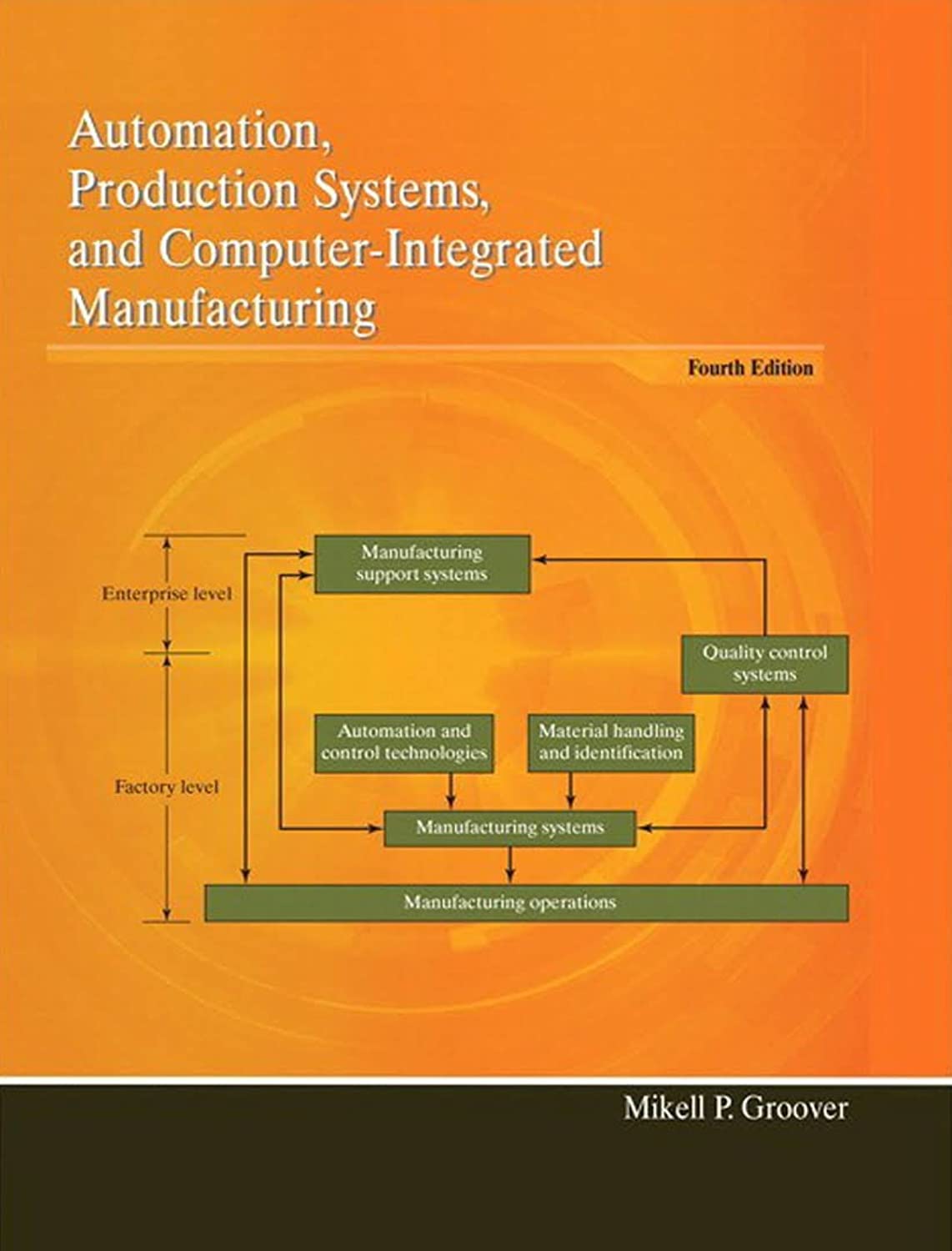

Automation Production Systems and Computer-Integrated Manufacturing 4th Edition by Mikell P. Groover Solution Manual

Original price was: $60.00.$30.00Current price is: $30.00.

Solution Manual for Automation Production Systems and Computer-Integrated Manufacturing, 4th Edition, Mikell P. Groover, ISBN-10: 0133499618 To get more information about this please send us E-mail to smtb7000@gmail.com

Description

🌟 Solution Manual for Automation Production Systems and Computer-Integrated Manufacturing, 4th Edition – Mikell P. Groover

Enhance your understanding of modern manufacturing with the Solution Manual for Automation Production Systems and Computer-Integrated Manufacturing, 4th Edition by Mikell P. Groover. This comprehensive guide provides step-by-step solutions, practical examples, and in-depth explanations for students, engineers, and professionals in manufacturing, industrial automation, and production engineering.

Book Details:

-

Title: Automation Production Systems and Computer-Integrated Manufacturing, 4th Edition

-

Author: Mikell P. Groover

-

ISBN-10: 0133499618

-

ISBN-13: 9780133499612

-

Format: PDF / Digital Solution Manual

📘 Table of Contents – Solution Manual Overview

Chapter 1: Introduction

An overview of manufacturing systems, automation trends, and the importance of integrated production technologies in modern industries.

PART I: Overview of Manufacturing

Chapter 2: Manufacturing Operations

Covers primary and secondary manufacturing operations, machining, forming, and joining processes.

Chapter 3: Manufacturing Metrics and Economics

Focuses on cost analysis, productivity metrics, and economic evaluation of manufacturing systems.

PART II: Automation and Control Technologies

Chapter 4: Introduction to Automation

Explains automated systems, levels of automation, and manufacturing system design principles.

Chapter 5: Industrial Control Systems

Covers open-loop and closed-loop control, feedback systems, and sensors in automation.

Chapter 6: Hardware Components for Automation

Discusses actuators, controllers, and devices used in automated manufacturing.

Chapter 7: Computer Numerical Control (CNC)

Detailed exploration of CNC machines, programming, and their role in precision manufacturing.

Chapter 8: Industrial Robotics

Focuses on robotic systems, manipulators, sensors, and applications in automated production.

Chapter 9: Discrete Control and Programmable Logic

Covers PLC systems, ladder logic programming, and control of discrete manufacturing processes.

PART III: Material Handling and Identification

Chapter 10: Material Transport Systems

Examines conveyors, automated guided vehicles (AGVs), and handling systems.

Chapter 11: Storage Systems

Covers storage technologies, automated warehouses, and inventory management.

Chapter 12: Automatic Identification and Data Capture

Includes barcoding, RFID, and data collection systems for production tracking.

PART IV: Manufacturing Systems

Chapter 13: Overview of Manufacturing Systems

Introduces manufacturing system types, configurations, and production strategies.

Chapter 14: Single-Station Manufacturing Cells

Details the design and operation of simple automated workstations.

Chapter 15: Manual Assembly Lines

Explains manual assembly processes and line balancing techniques.

Chapter 16: Automated Production Lines

Focuses on automated line design, integration, and performance optimization.

Chapter 17: Automated Assembly Systems

Covers robotic assembly, sensors, and automation strategies for complex products.

Chapter 18: Group Technology and Cellular Manufacturing

Explains cellular layouts, part families, and efficiency improvements.

Chapter 19: Flexible Manufacturing Cells and Systems

Highlights flexibility in machining, robotics, and reconfigurable manufacturing systems.

PART V: Quality Control Systems

Chapter 20: Quality Programs for Manufacturing

Covers total quality management, ISO standards, and process improvement.

Chapter 21: Inspection Principles and Practices

Explains measurement methods, statistical process control, and quality assurance.

Chapter 22: Inspection Technologies

Focuses on non-destructive testing, automated inspection systems, and metrology tools.

PART VI: Manufacturing Support Systems

Chapter 23: Product Design and CAD/CAM in Production

Discusses computer-aided design and manufacturing integration for efficient production.

Chapter 24: Process Planning and Concurrent Engineering

Highlights planning techniques, workflow optimization, and simultaneous engineering approaches.

Chapter 25: Production Planning and Control Systems

Covers scheduling, inventory control, and ERP systems for manufacturing operations.

Chapter 26: Just-in-Time and Lean Production

Explains lean principles, JIT production, and waste reduction strategies for high-efficiency systems.

🎯 Why Choose This Solution Manual?

-

Step-by-step solutions for all exercises

-

Clear explanations of automation and manufacturing concepts

-

Ideal for students, engineers, and professionals in industrial manufacturing

-

Boosts understanding of modern manufacturing systems, robotics, and lean processes

📥 Get the Solution Manual for Automation Production Systems and Computer-Integrated Manufacturing, 4th Edition and master modern industrial automation, CNC, robotics, and lean manufacturing techniques today.

https://testbankforyou.com/shop/